OK Couplings

When using the OK couplings for shaft connections, advantage is taken of the powerful oil injection method.

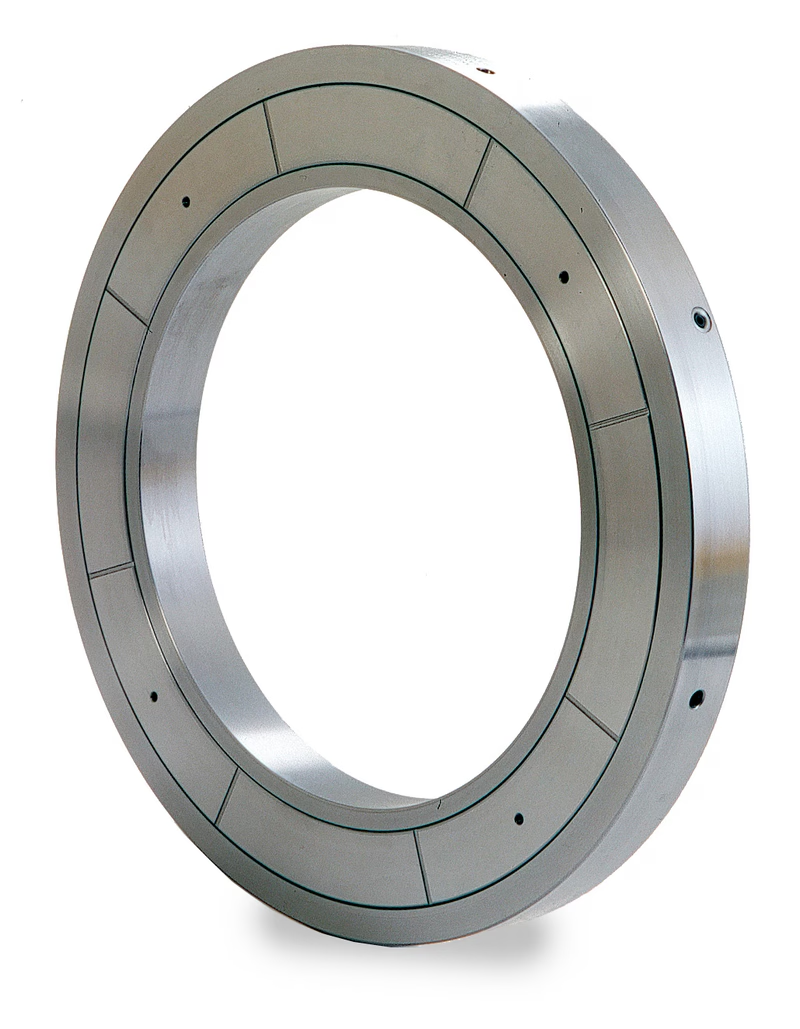

Preparation of the shaft is simple. No keyways to machine, no taper and no thrust ring. When mounting the OK coupling, a thin inner sleeve with a tapered outer diameter slides onto the shaft. A thick outer sleeve with a matching tapered inner surface fits onto the inner sleeve. Ordinary mineral oil is then injected between the sleeves. A built-in hydraulic jack drives the outer sleeve up the taper of the inner sleeve.

When the outer sleeve has reached its final position an interference fit is created – just as if the outer sleeve had been heated and shrunk on. But no heat is required, and the coupling can be removed as easily as it was mounted.

This powerful use of friction enables the OK coupling to transmit torque and axial loads over the entire area of the shaft. There are no stress raisers at the keyway. And no fretting when high shock or reversing loads exist.

Very large couplings, which previously could only be shrunk on after heating, can now be assembled cold with the OK method.

For further information about these products please contact your local SKF sales unit

Supergrip bolts

The same advanced design of OK Couplings has been applied to the coupling bolt. The Supergrip bolts represent a ‘quantum leap’ in improved technology for connecting rotating flange couplings. They are on the job – on land and at sea – delivering performance that supports the claim that they are better than any other coupling bolt available on the market.

Prior to Supergrip bolts, fitted bolts had to be ‘slugged’ into place with a sledgehammer. This followed time-consuming honing of the holes and grinding of the bolts. Even with improved technological methods for fitting bolts, it is hard to achieve an interference fit. After each assembly and surface restoration, a small gap remains, increasing the chance of misalignment and subsequent galling of standard studs. Eventually the bolts have to be replaced. With a gap, the risk of coupling slippage at an overload situation is increased, causing potential balancing problems.

The Supergrip bolt eliminates these problems. Supergrip bolts are a superior solution for connecting flange couplings. Compared with traditional bolt systems, Supergrip bolts are much easier to install and remove. The bolts are inserted and removed by hand and with a clearance, eliminating the risk of seizure. The bolt is hydraulically expanded and tightened into the coupling bolthole, using a set of portable tools. The need for an overhead crane and time-consuming slugging of bolts is eliminated. Once the holes have been line-bored for initial installation, there is no need for further reaming or boring of holes. Thus the use of Supergrip bolts eliminates uncertainty about the length of downtime needed for removing and installing bolts at outages. Costs are cut and the length of future outages is significantly decreased.

The oil-injection method used for removing the reusable bolts was pioneered by SKF. Originating in Sweden, this technology is based on nearly a half century of experience in the engineering and manufacture of couplings for the marine market, and since the late 1970s, for the utility industry also.

Hydraulic rings and propeller nuts

The time saving technology from SKF

Traditionally, ship propellers are mounted on a tapered shaft end with a nut and key. The torque is transmitted through friction of the mating surfaces and the key performs a stand-by function if the friction is insufficient.

On mounting, the propeller is driven up the taper by heating the propeller hub and driving in keys between the nut and the hub, or by using a hydraulic press or even flogging the nut to achieve the required axial drive up.

All these methods are time consuming and difficult to manage due to the large forces required. For large propellers the methods are unacceptable.

These conventional methods are especially troublesome when dismounting propellers from shafts.

Withdrawal forces are large and fretting damage often occurs on the contact surfaces. Due to the large forces, withdrawal tools are often bulky, expensive and difficult to handle. The dismounting process is therefore very time consuming.

The SKF oil injection method combined with a hydraulic ring or nut from SKF solves all these problems and simultaneously eliminates the use of keys and keyways.

This method is fully accepted by all the worlds leading classification societies and hundreds of references for all types of vessels are available.